Equipment Used In Volcano Surfing

Lava Surfers who come into frequent contact with molten metal an lava need protective clothing that transfers heat very slowly. Carbon clothing has the slowest heat transfer rate of any fabric on the market. And thanks to its unique composition many molten metals will not adhere to Carbon clothing fabrics. This provides surfers with a remarkable level of protection against the hazards of contact with molten metal and lava.

Carbon clothing also safeguards volcano surfers against the dangers of electricity, with superior protection against electrical arcing. In fact, NFPA 70E tests show that ounce for ounce carbon clothing outperforms every other protective fabric on the market. And because carbon clothing is breathable, comfortable, and odor resistant, volcano surfers don't have to sacrifice comfort to gain the superior protection carbon clothing provides.

"Flame resistance is commonly

measured by the highest Limiting Oxygen Index (LOI), the amount of oxygen

needed to support combustion. The higher the LOI value, the more flame-resistant

the material.

When exposed to intense heat or flame, carbon clothing fibers will carbonize and then expand, eliminating any oxygen content within the fabric. This characteristic enables carbon clothing to outperform any and all FR fibers and fabrics currently available. The LOI rating for the majority of the FR fabrics on the market is often achieved by adding a flame retardant finish to the fiber or fabric. The treatments can deteriorate after continued UV exposure and normal laundry care. Carbon clothing , on the other hand, is never treated with any additives or chemicals. UV exposure, laundry and chemicals will not significantly affect the performance properties.

Limit of Oxygen Index (LOI)

CERTIFIED LABORATORY TESTING

In formal testing, the current leading FR fabrics burn, shrink, char, crack and decompose. These FR fabrics ignite during flammability testing, and often have problems passing the shrinkage test. Under the same testing conditions, carbon clothing will not ignite, burn or shrink and successfully disburses the heat energy for periods in excess of 60 seconds. Even after exposing carbon clothing to temperatures exceeding 2600, for a period exceeding 120 seconds, carbon clothing will not ignite, burn or shrink. Below are the testing results comparing carbon clothing with the leading FR materials available in the market today.

Carbon Clothing versus Leading FR Fabric TPP Comparison Testing

When seconds could be the difference between escaping a dangerous situation unscathed and suffering severe burn injury, the added protection of apparel made with carbon clothing can make the difference. Thermal manikin tests were conducted to compare the protective capabilities of carbon clothing in relation to Nomex, INDURA and INDURA Ultra Soft. Manikin testing is used to compare the relative thermal protective performance of fabrics by exposing full-size garments to laboratory simulations of a flash fire. Results are reported in percentage of body burn. The added protection of apparel made with carbon clothing is dramatically illustrated after four seconds of flash flame exposure. In this extreme environment, only 12.4% of the surface area of the manikin suffered the equivalent of 2nd or 3rd degree burns compared to results ranging from 40% to over 60% burns from INDURA Ultra Soft, INDURA and Nomex.

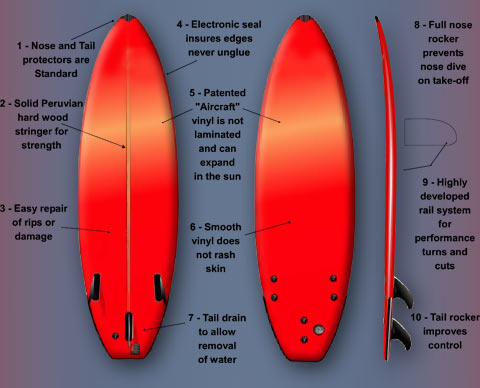

Special Designed Board For Hot Water

Waxed with Heat Resistance Coating